Yamaha YICS Diagnostic and Repair

June 17, 2021

I had been having some issues getting my XZ550 to start and fortuitously stumbled upon a write-up about the YICS system through an archived version of XZ550.com. One of the tell-tale signs of a leaky YICS is a difficulty in starting the motorcycle. Another symptom is engine hunting at idle. I decided to write up this post to explain my process for repairing the YICS, there doesn’t seem to be much information about the repair left on the internet.

The first step is diagnosing whether your YICS has an internal or external leak. Begin by removing only the screw holding down the chrome cover. To check for an internal leak, attach a length of hose to each port and blow. You should feel resistance. If you feel air coming out of the other hose, then you have an internal leak. To check for an external leak, plug one of the hoses, submerge the YICS in water, and blow through the open hose, making sure to test each port. If you see any bubbles, then there is an external leak in the YICS. External leaks are easy to fix, simply mix up some epoxy and seal the hole. I would suggest coating the YICS in soapy water and blowing through each port until you see bubbles coming from the leak.

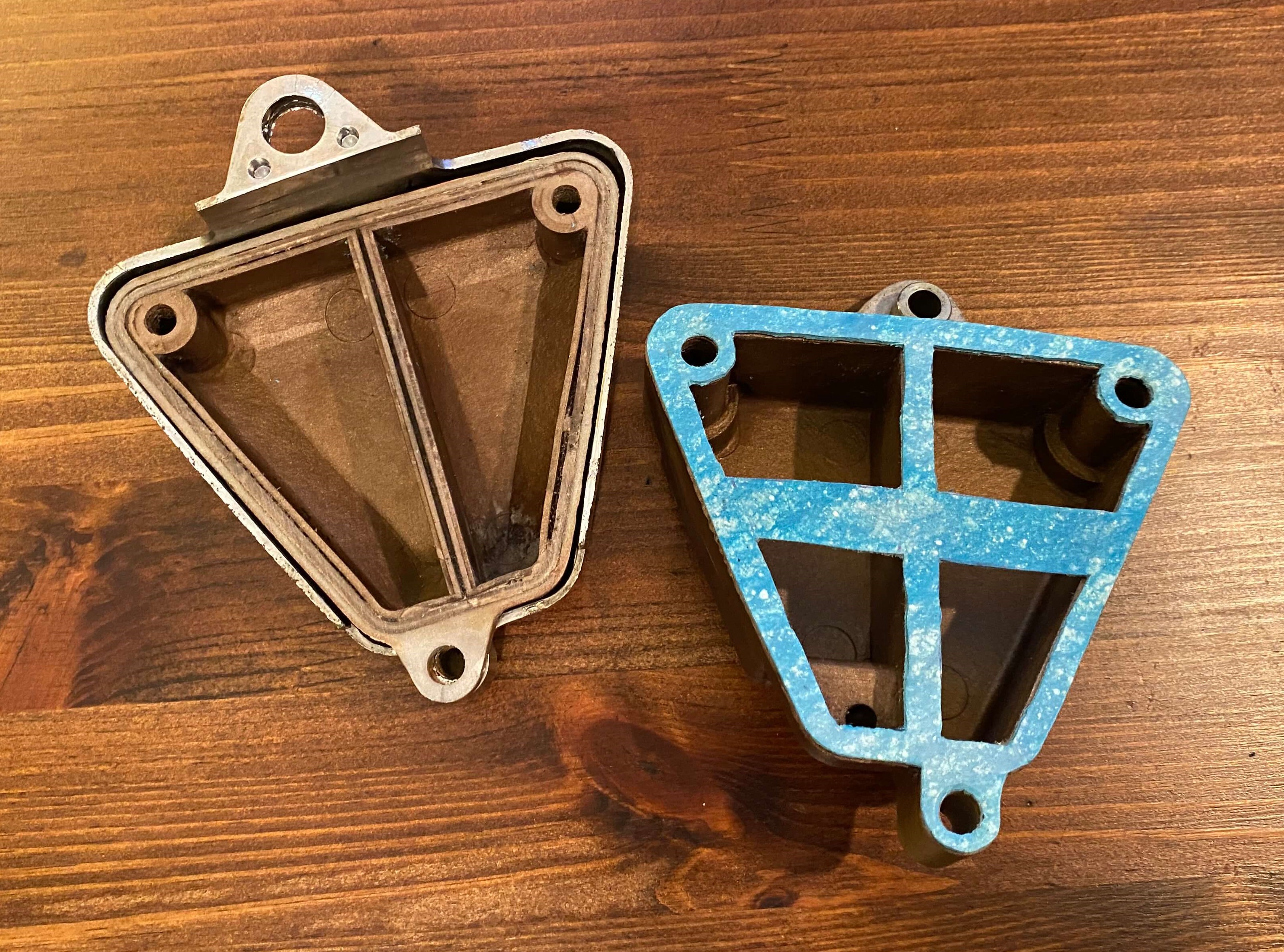

Internal leaks, on the other hand, are not an easy fix. I’ve seen some people suggest taking a bandsaw to your YICS, but I personally don’t recommend that. As long as you have time and patience, you can split the YICS in half with a razor blade. Regardless of which method you use, you want to cut along the seam. I had to run the razer blade around the seam multiple times before I was able to cut through. Next you need to fabricate a gasket for the YICS. I used the YICS as a template to cut out the perimeter of the gasket, cut out the holes with leather punches, and cut out the center portion after taping the edges of the gasket to the YICS. It’s recommended to add the horizontal supports seen in the picture below to your gasket for additional support. I went with 1/32” Oil-Resistant Aramid/Buna-N Gasket Material. The last step is to apply a thin layer of gas-resistant liquid gasket to each half of the YICS, sandwich the gasket, and screw everything down.

If you find that your YICS is beyond repair, you can simply cap the ports on each cylinder head. Personally, I worry about repeatedly screwing and unscrewing the tapping screws into the plastic of the YICS.

~ JHE